FANUC Robot Controller - R Model J / J2 / J3

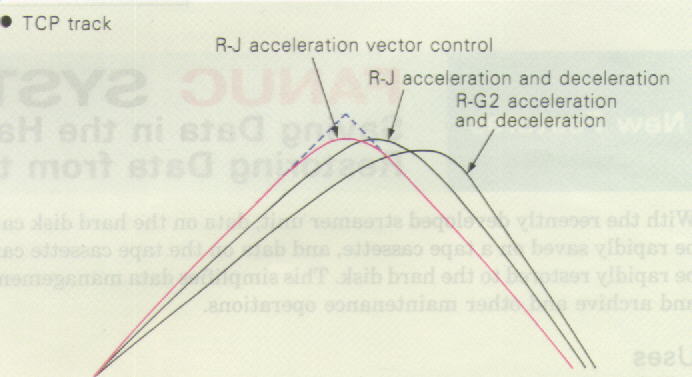

The ' Fanuc R model J ', ' Fanuc R model J2 ' and ' Fanuc R modle J3 ' robot controllers have the capability of controlling from 3 to 6 axis on the robot, and providing multi-axis simultaneous motion. In addition to 6 robot axis, the controller has the capacity to control 10 additional axis. Additional axis can be used to extend the robot work area in the form of linear bases or gantries, but can also perform other simultaneous positioning functions such as welding manipulators and door / boot / hood openers. The controller offers linear and circular motion path types, together with specialist welding motion types - i.e. Weave Welding motions.

Controllers of this nature have been used to with the following robots :-

LRMate, LRMate 100, LRMate 200,

A520,

M400, M410, M500, M710,

S6, S12, S16, S420, S430, S500, S700, S900,

Arcmate 100, Arcmate 120,

The controller has a limited number of operator push buttons of the front panel.

The teach pendant comprises a large multi-line LCD display, some LED status indicators and a medium sized flat keyboard. The teach pendant is characterised by its square plastic body, and twin rubber covered ' Deadmans Handles ' on the back of the teach pendant.

Inside the controller, a backplane PCB supports a number of modular PCB's mounted directly in the backplane rack. Up to 9 amplifiers for the servo motors are mounted inside the cabinet, although the 6 primary robot axis amplifiers are incorporated into one block.

Programs are stored in static RAM memory with a battery to retain programs during power off periods.

All robots are fitted with absolute positioning systems. Absolute Pulse Coders provide absolute position feedback, with batteries provided to retain position data during power off periods.

The robot has the capability to work with vision systems if required.