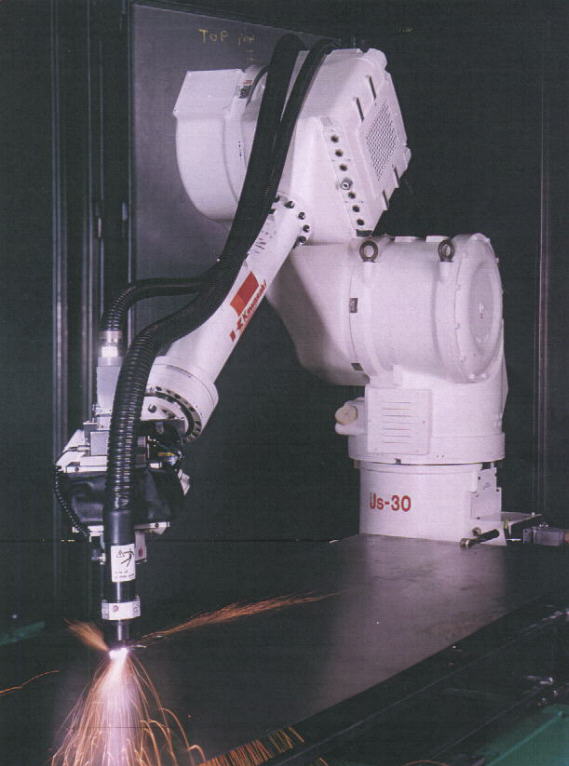

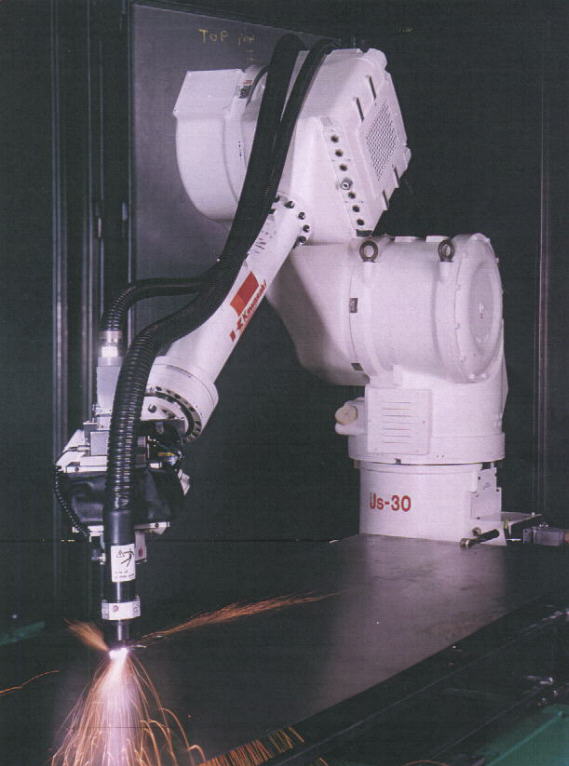

| Kawasaki robot fine plasma cutting : |

|

| Introduction : | |

Production of low quantity, low cost pressed steel panels is generally prohibited by the high cost of the trimming function of press tooling. Robotix has invested a considerable amount of engineering expertise in the design and manufacture of an effective robotic solution to trim tools. We have worked with a number of manufacturers before settling with Fanuc as our preferred supplier of robots for 3 dimensional plasma cutting. |

|

| Kuka robot for fine plasma cutting : |

|

| Kawasaki JS30 robot in fine plasma cell built by Robotix : |

|

| Solution : | |

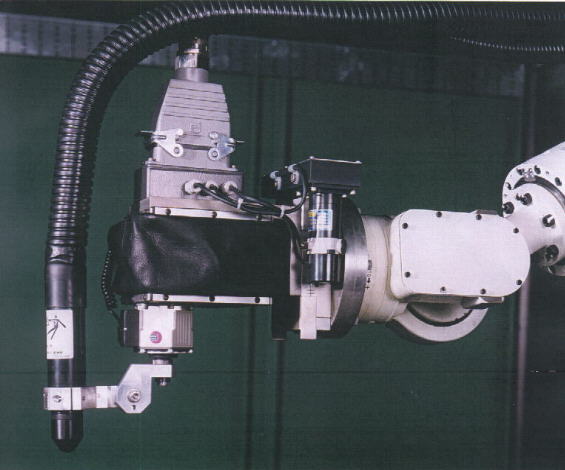

With the majority of robots, the most essential part of the 3 dimensional fine plasma cutting system is the trepanning head. The trepanning head allows any robot, however poor its short motion path control, to produce high quality small holes. The trepanning head has a motion range of 50mm in the 'X' and 'Y' directions, and is fully programmable, allowing any desirable shape to be produces within this envelope. In addition the trepanning head is fitted with a 'Z' axis, allowing the head to follow any deviations in the panel to ensure that the plasma arc length is held constant. Arc length control is particularly important in fine plasma cutting, as excessive variation in arc length causes hugely differing cut quality, or at worst, arc failure and torch damage. |

TREPANNING HEAD CNC |

| Kawasaki JS30 fitted with Robotix trepanning head |

|

| P.S. : |

Having delivered robotic fine plasma cutting system to users as far apart as Telford ( Shropshire, UK ) and Mumbai ( India ), Robotix is currently working with Fanuc Robotics UK to develope the next generation fine plasma cutting systems. Following extensive developments by Fanuc Japan in position control, we are now able to offer plasma cutting and height control without the trepanning head. |