Recent additions to their customers product range caused a re-think of the manufacturing processes in one particular area - how to secure a folded flange to the remaining panel.

Compound bends around the front edge of the cabinet could allow the flange to vibrate against the cabinet side during operation, unless the flange is secured.

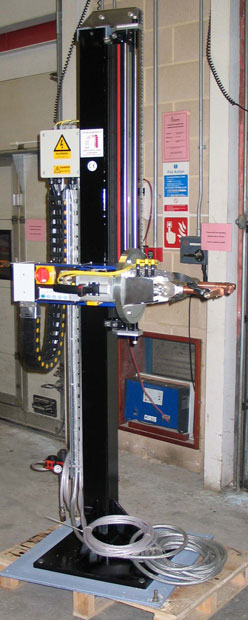

After some discussion, Robotix was contracted to design and manufacture a suitable spot welding machine, capable of attaching the flange to the side panel - with no visible marking to the outside of the panel.

Strategically positioned within the press brake cell, the robot offers the flanged edge of the panel to the spot welder. The spot welding gun has two working positions, allowing the robot to complete the spot welding in one operation.

( The photograph shows the spot welding machine in our loading bay - ready for delivery to the customers works. )